The rapid growth of wireless temperature monitoring Australia can be attributed to three key factors: food safety compliance, operational efficiency, and asset protection. Businesses across industries such as food service, healthcare, pharmaceuticals, and industrial operations are rapidly adopting this technology to meet strict regulatory requirements while also reducing operational costs.

The increased adoption of wireless temperature monitoring Australia systems is part of a larger trend away from manual logging methods and toward fully automated solutions. Traditional temperature checks consume valuable staff time and can leave dangerous monitoring gaps. In contrast, wireless temperature monitoring Australia solutions provide continuous, real-time data and send instant alerts when temperatures move outside safe limits.

This advanced technology is specifically designed to meet Australia’s environmental and logistical challenges — from coping with extreme industrial heat to preserving cold chain integrity over vast distances. The combination of regulatory compliance, technological innovation, and measurable cost savings has made wireless temperature monitoring Australia one of the fastest-growing safety and efficiency tools in the market today.

Why Is Wireless Temperature Monitoring Becoming Essential in Australia?

1. Ensuring Food Safety Compliance

Food safety compliance Australia demands have made wireless temperature monitoring indispensable for businesses handling temperature-sensitive products. Australian regulations require strict adherence to temperature control standards, particularly in food service, healthcare, and pharmaceutical sectors. Wireless systems automatically document temperature readings at regular intervals, creating comprehensive audit trails that satisfy regulatory requirements without manual intervention.

2. Improving Operational Efficiency

The shift towards operational efficiency stems from real-time data access that eliminates time-consuming manual checks. Staff no longer need to physically visit multiple locations with clipboards, freeing them to focus on core business activities. Automated alert mechanisms send instant notifications via SMS, email, or app when temperatures deviate from safe ranges, enabling immediate corrective action before products are compromised.

3. Protecting Assets

Asset protection becomes critical when considering the financial impact of temperature failures. A single refrigeration breakdown can destroy thousands of dollars worth of perishable goods within hours. Wireless monitoring systems act as an insurance policy, detecting problems early enough to salvage inventory. The technology proves equally valuable for protecting sensitive equipment in industrial environments where extreme temperatures can damage machinery or compromise production processes.

4. Overcoming Geographic Challenges

Australian businesses face unique challenges with vast geographic distances and remote locations. Wireless systems provide centralised monitoring across multiple sites from a single dashboard, allowing managers to oversee operations in Sydney, Melbourne, and regional facilities simultaneously. Battery-backed gateways ensure continuous monitoring even during power outages, addressing concerns about Australia’s occasional extreme weather events that can disrupt electricity supply.

More about: Food Safety Audits vs Inspections What’s the Key Difference?

How Do Wireless Temperature Monitoring Systems Work?

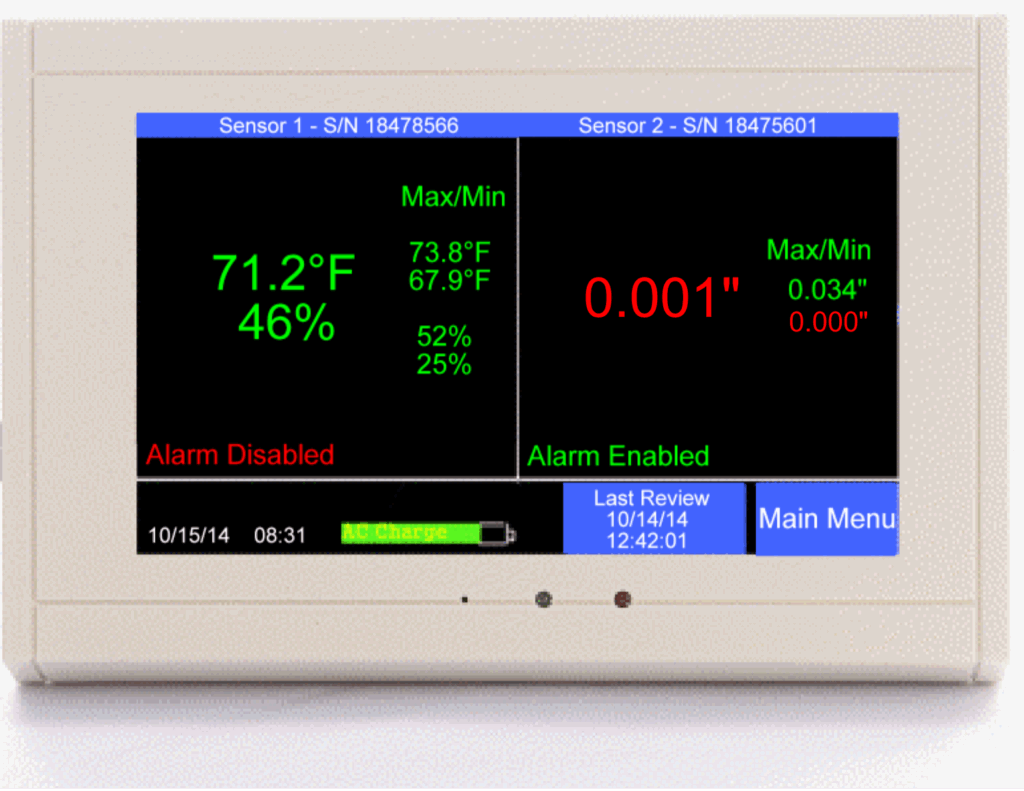

Wireless temperature monitoring systems rely on wireless sensors technology that collects and transmits temperature data without physical cable connections. These sensors contain precision thermistors or thermocouples that measure ambient or probe temperatures, paired with radio frequency transmitters that send readings to a central gateway or receiver.

The Role of the Gateway

The gateway acts as the system’s hub, collecting data from multiple sensors across a facility and forwarding this information to cloud-based platforms via internet connectivity. This architecture allows businesses to monitor temperatures from anywhere using computers, tablets, or smartphones.

Understanding Temperature Readings

Real-time temperature readings update at regular intervals—typically every 1 to 15 minutes depending on system configuration. The continuous data stream creates a comprehensive temperature history that gets stored in the cloud, enabling businesses to track trends, identify patterns, and maintain detailed records for compliance purposes.

The Importance of Automated Alerts

Automated alerts form the critical safety net of these systems. Users set specific temperature thresholds for each monitoring location based on regulatory requirements or product specifications. When a sensor detects temperatures outside these parameters, the system immediately triggers notifications through multiple channels:

- SMS text messages to designated staff members

- Email alerts to management teams

- Push notifications via mobile applications

- Audible alarms at on-site gateways

The alert mechanism operates 24/7, providing constant vigilance even outside business hours. Battery-backed gateways ensure monitoring continues during power failures, whilst sensors with extended battery life (2-10 years) maintain consistent data collection without frequent maintenance interruptions. This redundancy guarantees that temperature-sensitive assets remain protected regardless of external circumstances

What Benefits Drive the Rapid Adoption of Wireless Temperature Monitoring?

Why are Australian businesses rapidly embracing wireless temperature monitoring? The technology delivers measurable cost savings whilst ensuring regulatory compliance through automated, accurate data collection that eliminates human error and manual labour.

The financial impact proves substantial across multiple operational areas:

1. Cost Reduction and Asset Protection

- Reduce stock loss through instant alerts that prevent spoilage before it occurs

- Energy cost management via detailed consumption patterns that identify inefficient equipment, potentially leading to significant savings as outlined by Energy Star

- Real-time visibility into temperature fluctuations protects high-value pharmaceutical and food inventories

2. Compliance and Administrative Efficiency

- Simplify audits with automatically generated temperature logs and historical data reports

- Regulatory compliance becomes effortless as systems maintain continuous documentation required by Australian food safety standards

- Digital records replace cumbersome paper-based systems, reducing administrative burden by up to 70%, a task that would typically require extensive administrative management

Real-World Impact: Melbourne Food Service Provider

A Sydney-based catering company managing 12 refrigeration units experienced recurring stock losses averaging $8,000 monthly due to undetected temperature breaches. After implementing wireless temperature monitoring with SMS alerts, the business achieved:

- 87% reduction in spoilage incidents within three months

- $6,960 monthly savings in prevented stock loss

- Complete elimination of manual temperature checks (saving 15 staff hours weekly)

- Zero compliance violations during health inspections

The system paid for itself within eight weeks whilst providing continuous protection against future losses. This pattern repeats across healthcare facilities, pharmaceutical warehouses, and industrial cold storage operations throughout Australia, explaining why wireless temperature monitoring in Australia is growing rapidly across diverse sectors seeking similar operational improvements.

Which Features Make Wireless Temperature Sensors Suitable for Australian Environments?

What design characteristics allow wireless sensors to withstand Australia’s demanding conditions?

Wireless temperature sensors built for Australian environments incorporate ruggedised housings rated for extreme temperature ranges (-40°C to +85°C) and high humidity levels, making them reliable in harsh industrial settings, cold storage facilities, and outdoor applications. These sensors feature IP-rated enclosures that protect internal components from dust, moisture, and corrosive substances commonly encountered in food processing plants, pharmaceutical manufacturing, and agricultural operations.

How do power options for sensors address different operational requirements?

Australian businesses can select from multiple power configurations based on their specific monitoring needs:

- Coin cell batteries: Provide 2-5 years of maintenance-free operation for standard temperature monitoring applications

- AA batteries: Deliver 5-10 years of service life in low-transmission frequency scenarios

- Power over Ethernet (PoE): Eliminates battery replacement concerns entirely for permanently installed sensors

- Wi-Fi powered options: Combine connectivity and power delivery through existing network infrastructure

What role do cloud-based monitoring dashboards play in sensor effectiveness?

Cloud-based monitoring dashboards transform raw sensor data into actionable intelligence through intuitive visualisation tools, historical trend analysis, and customisable reporting functions. These platforms enable multi-site monitoring from any internet-connected device, allowing facility managers to oversee temperature-critical assets across multiple locations simultaneously. The dashboards automatically generate compliance reports, reducing audit preparation time from hours to minutes whilst maintaining complete data integrity for regulatory inspections.

Do long battery life sensors reduce operational costs?

Extended battery longevity directly translates to lower maintenance expenses and reduced labour requirements for battery replacement across large sensor networks, particularly beneficial for businesses monitoring hundreds of temperature points simultaneously.

What Role Do Specific Products Play in Supporting This Growth?

Specific wireless temperature monitoring products demonstrate the practical application of advanced features that Australian businesses demand. The Hygeian WTX-275 exemplifies this trend, offering tool-free installation sensors that eliminate setup complexity whilst delivering professional-grade monitoring capabilities. Its internal sensor design suits fridge and freezer environments perfectly, providing precise readings where temperature control matters most.

The WTX-275’s alarm messaging capabilities address a critical business need: immediate notification when temperatures breach safe thresholds. This system sends alerts through multiple channels—SMS, email, and app notifications—ensuring responsible personnel can respond quickly regardless of their location. Long-range wireless communication extends up to 100 metres indoors and 500 metres in line-of-sight conditions, making it viable for large facilities without requiring extensive infrastructure.

However, the FT4X series from Fox Thermal further complements this growth by providing robust solutions for various industries requiring precise temperature control.

Comprehensive support services separate market-leading products from basic alternatives:

- Calibration certificates provide documented proof of accuracy for regulatory compliance

- Annual battery replacements maintain consistent performance without user intervention

- Technical support resolves issues promptly, minimising downtime

- Warranty coverage protects the investment and demonstrates manufacturer confidence

These service elements transform a monitoring device into a complete solution. Australian businesses value this holistic approach because it reduces internal resource requirements whilst maintaining audit-ready documentation. The combination of robust Hygeian WTX-275 features with ongoing manufacturer support creates a compelling value proposition that accelerates adoption across sectors where temperature control directly impacts product quality, safety compliance, and financial performance.

How Does Wireless Temperature Monitoring Improve Compliance and Operational Efficiency?

Wireless temperature monitoring systems directly address health and safety regulations Australia mandates by providing continuous, documented proof of temperature control across food storage, pharmaceutical facilities, and healthcare environments. These automated systems generate time-stamped records that satisfy Food Standards Australia New Zealand (FSANZ) requirements and state-specific health department audits, eliminating the risk of incomplete or inaccurate manual logs that often lead to compliance failures.

Benefits for Australian Businesses

Manual labour reduction represents one of the most tangible benefits for Australian businesses implementing these systems. Staff no longer need to walk through multiple cold rooms, freezers, or storage areas several times daily with clipboards and thermometers. The technology handles routine temperature checks automatically, freeing employees to focus on value-adding tasks like customer service, food preparation, or quality control activities that genuinely require human judgment.

Immediate Notifications for Critical Events

The power of accurate remote data access becomes evident during critical temperature events. When a refrigeration unit begins failing at 2 AM, managers receive instant SMS or email alerts on their mobile devices, regardless of their physical location. This immediate notification enables swift response actions—contacting maintenance technicians, relocating stock to backup storage, or adjusting equipment settings—before thousands of dollars worth of perishable goods spoil.

Centralised Oversight for Multi-Site Operations

Cloud-based dashboards provide real-time visibility across multiple sites simultaneously, allowing regional managers to monitor temperature compliance at dozens of locations from a single screen. This centralised oversight capability proves invaluable for multi-site operations like restaurant chains, aged care facilities, or pharmaceutical distributors managing temperature-sensitive inventory across vast Australian distances. The data accuracy these systems deliver removes guesswork from decision-making processes, replacing reactive problem-solving with proactive temperature management strategies.

Conclusion

The reasons behind the rapid growth of wireless temperature monitoring in Australia become clear when we look at the combination of regulatory requirements, technological advancements, and economic feasibility.

The future of temperature monitoring in Australia indicates that it will be widely adopted as costs continue to decrease and capabilities expand.

Industries such as food service, healthcare, pharmaceuticals, and manufacturing now see these systems as essential infrastructure rather than optional upgrades. The proven return on investment—through reduced waste, avoided compliance violations, and eliminated manual logging—makes wireless monitoring financially attractive even for smaller businesses.

Improvements in technology provide longer battery life, better connectivity, and more user-friendly cloud platforms that require little technical knowledge. Australian suppliers are increasingly offering comprehensive support packages including calibration, maintenance, and technical assistance that eliminate implementation obstacles.

Ready to protect your assets and streamline compliance? Explore wireless temperature monitoring solutions designed specifically for Australian conditions. Contact a specialist today to discover how automated monitoring can transform your operations while ensuring regulatory compliance and safeguarding your valuable inventory.

Learn about: Food Safety Audits vs Inspections What’s the Key Difference?

FAQs

Wireless temperature monitoring uses sensors to continuously measure and transmit temperature data to a central system, helping businesses comply with food safety regulations, protect assets, and improve operational efficiency across sectors like food service, healthcare, and pharmaceuticals.

These systems automatically document temperature readings at regular intervals, creating audit-ready digital logs that satisfy Australian regulatory requirements such as FSANZ and state health department standards, eliminating gaps and human error associated with manual checks.

Sensors with thermistors or thermocouples measure temperatures and transmit data via radio frequency to a central gateway. The gateway forwards this data to cloud-based platforms, enabling real-time monitoring from computers, tablets, or smartphones.

Benefits include continuous compliance documentation, reduced manual labor, early alerts for temperature deviations, asset protection, operational efficiency, multi-site monitoring, and cost savings from prevented spoilage and energy optimization.

Users set temperature thresholds for sensors, and the system immediately triggers notifications via SMS, email, push alerts, or audible alarms when temperatures fall outside safe ranges, ensuring swift corrective action to prevent product loss.

Yes. Sensors are built with rugged housings and IP-rated enclosures, operating across wide temperature ranges (-40°C to +85°C) and high humidity levels, suitable for industrial, cold storage, and outdoor applications.

Cloud dashboards consolidate data from multiple sites, allowing managers to track temperature trends, generate compliance reports, and make informed decisions remotely, ensuring consistent control across large or geographically dispersed operations.

Absolutely. Automated monitoring reduces manual labor, prevents spoilage of perishable goods, lowers energy costs, and ensures regulatory compliance, often resulting in significant ROI within weeks of implementation.

Features include real-time multi-location monitoring, long-range wireless communication, battery-backed gateways for power outages, and centralised dashboards that enable managers to oversee dozens of sites from a single interface.

Food service, healthcare, pharmaceuticals, cold storage, and industrial operations all gain from continuous temperature tracking, regulatory compliance assurance, asset protection, and operational efficiency.